-

SPONSORED

-

-

Workholding

Rail Manufacturer Moves Full Steam Ahead with Safe, Efficient Workholding Solution

All World Machinery Supply paired a hydraulic power unit with remote operating capabilities in a custom workholding system for Ahaus Tool & Engineering.

Read MoreJergens Workholding Lineup Enables Automated, Continuous Machining

IMTS 2024: Jergens Inc.’s lineup focuses on quick-change workholding solutions and automation capabilities, such as the custom MT-S spindle gripper for continuous machining.

Read MoreWorkholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

WatchUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

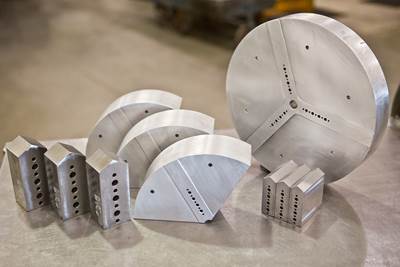

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreDillon Reversible Hard Jaws Provide Secure Parts Gripping

The company’s reversible hard jaws are designed to decrease the time and cost of tool setups.

Read MoreDestaco Electric Power Clamps Enable Flexible Production

The 92W series electric power clamps feature integrated intelligence to reduce the need for additional components.

Read MoreDillon Pin Location Jaws Hold Sensitive Parts Without Deformation

Each jaw is CNC milled to provide maximum accuracy of workpiece location, enabling air chucks to hold sensitive workpieces firmly.

Read MoreStafford Shaft Collars Enable Adjustments Without Tools

Stafford shaft collars and mounts feature handles and thumb screws to convert standard shaft collars to quick-adjust types.

Read MoreSMW Autoblok Vise System Provides Omnidirectional Clamping

The Plus5 V5 Zero Point Vise system interfaces with all industry-standard products using 52 mm or 96 mm pin spacing, enabling it to readily become part of existing workholding systems.

Read More