-

SPONSORED

-

-

Articles

A New Face To Parts Chucking

Mechanical face drivers offer an alternative to other types of traditional chucking methods. Using mechanical face drivers for turning applications often provides increased flexibility and lower cycle times. Face drivers turn both very small and very large workpieces, and they also allow interrupted and heavy cuts. The major benefit of a face driver is that it allows the workpiece to be completely turned from one end to the other in one operation.

Read MoreGet Lean, Go Global

A successful manufacturing company must achieve world-class capability within its walls. At the same time, a company has to go after global business opportunities. Hanel Corporation (New Berlin, Wisconsin) is a case in point. It has implemented several U-shaped production cells that help the company keep costs down and productivity up. At the same time, company leaders have aggressively courted customers in countries around the world by offering both tangible and intangible values.

Read MoreWhen Disaster Strikes

If your equipment was damaged or destroyed by flood or fire, would you know what to do?

Read MoreMaking A Flexible Machine Tool More Flexible

Multitasking cutting tools can maximize the flexibility of multitasking machines.

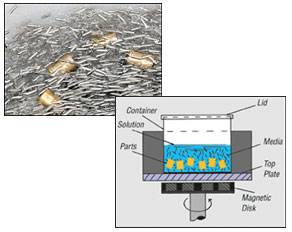

Read MoreDeburr Small Parts With Swarming Stainless Pins

This deburring system uses magnetism to excite small pins that remove light burrs from small, non-ferrous parts.

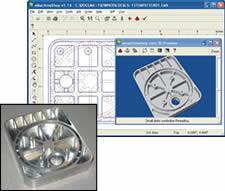

Read MoreConnecting CAD And Measurement

This software can use the CAD file to generate an inspection program automatically, so inspection personnel don't have to spend time scrutinizing 2D drawings.

Read MoreManufacturing In Transition

The Future of Machining - 2005 The role of machining will evolve as manufacturing adapts to pervasive trends. Here is an outlook on the forces shaping the manufacturing industry.

Read MoreA Startup Shop In The Digital Age

This shop is building a future based on the creative and productive potential of machining.

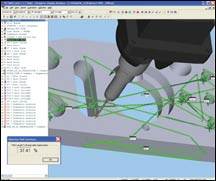

Read MoreThe Changing Face Of CNC Programming

The Future of Machining - 2005 Efforts to create a CNC-usable product data model are inching forward, but in the meantime, advances in CAM software will make the programmer's job function super-efficient rather than superfluous.

Read MoreSurviving Global Competition Through Aggressive Business Practices

The Future of Machining - 2005 Shops will become more aggressive in the way they quote new work and determine true process efficiency.

Read MoreMachining Outside The Shop

The Future of Machining - 2005 The number of machine tools operated by non-machinists outside the machine shop will increase.

Read MoreAn Alternate Contract Machining Business Model

The Future of Machining - 2005 The number of shops that will not communicate with or even know their customers will increase.

Read More