Articles

Sawing On A Machining Center

One of the unusual operations that the PBZ NT five-axis machining center can perform is sawing with a blade as much as 20 inches in diameter.

Read MoreThe Multi-Process Machine Mindset

Installing a machine tool that combines milling, turning, boring and other processes changed this job shop’s outlook.

Read MoreLearn Before Lifting

A safety feature on this magnetic lifter determines whether the load falls within the safe capacity of the device.

Read MoreCermets Get Assertive

The toughness of this material has improved. Today, the applications for cermet inserts go well beyond finishing.

Read MoreHow To Succeed At Failure

Your cutting tool’s failure mode may be telling you what to change about the process. Not every failure mode is the same, and one mode is preferable to all the others.

Read MoreNet-Shape Chucking Increases Hard Turning Accuracy

Heat treating a round, thin-wall part can distort the part's diameter. This lathe chuck grips an out-of-round part without forcing the workpiece perfectly round, which eliminates the spring-back effect after machining and removal from the chuck to enable a more accurate hard-turning operation.

Read MorePrepped For Success

A few months ago, I wrote about the noticeable increase in startup machine shops (

Read MoreGetting The Most From Creep-Feed Grinding

No other process can do what creep-feed grinding can do. Recent tests show even more can be gained by optimizing every element of a creep-feed system.

Read MoreHow Clean Is "Precision" Clean?

Specially engineered aqueous cleaning equipment is normally necessary to obtain the cleanliness levels automakers demand. There are general system attributes that a precision cleaning system should possess.

Read MoreMachining Composites By Conventional Means

Composites machining is dusty, messy and hard on tools. But this company accepts these difficulties, and machines the material using standard metalworking processes and equipment.

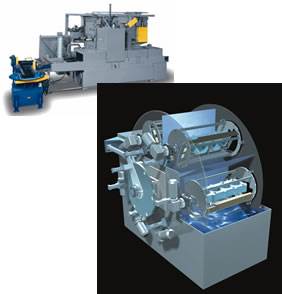

Read MoreMilling On A Grinding Machine

A grinding machine is not a machining center, but it can sometimes take on milling and drilling (or even turning) to make the overall process more efficient.

Read MoreRethinking Redundancy

Series production is a more economical choice today, says this supplier of machining systems. Machining technology is now reliable enough that parallel production may represent a costly level of excess in high-volume production.

Read More