What Your Handbook Isn’t Telling You

Tony Schmitz, professor at the University of North Carolina at Charlotte, gives a presentation on machine tool dynamics. Learn the role that this concept plays in realizing your optimal machining center performance.

Share

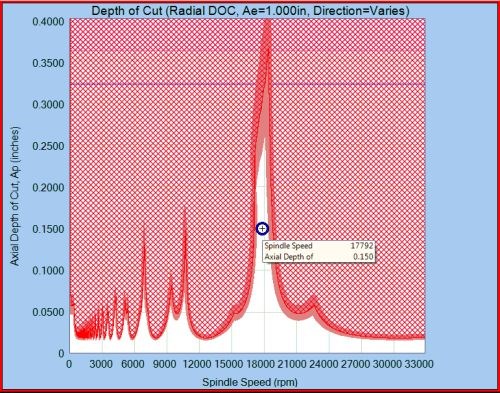

This example of a stability diagram shows how increased depths of cut that are possible within specific, narrow bands of spindle speed. Sometimes a deeper cut is possible at a higher speed than where the process is currently running.

— The best-performing speeds for a given machining process often do not correspond to machining handbook values.

— Your process might actually deliver better tool life, surface finish and/or metal removal rate if you increase the speed rather than reduce it.

After watching Dr. Schmitz’s presentation, see an example of turning up the speed in this video, and read about how one shop is applying this phenomenon to realize the most efficient performance from its own machine tools.

Related Content

-

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

-

Additive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

-

Fryer Milling Machine Provides Fast Setup, Simple Programming

The MB-R toolroom bed mill is reportedly capable of single- or multi-part production with a 0.0002" accuracy.