Timothy W. Simpson Paul Morrow Professor of Engineering Design & Manufacturing

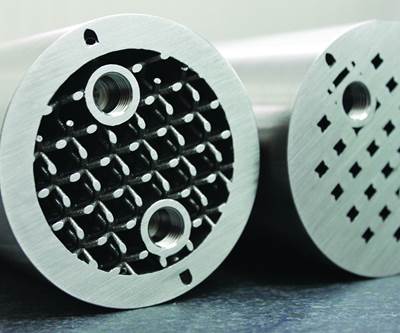

Lightweighting with Lattices

Instead of building components as a solid, building them as a network of unit cells may improve material utilization and performance.

Read MoreManufacturing for Design, Not the Other Way Around

AM allows us to make any shape we want, without having to adapt the design for the manufacturing process.

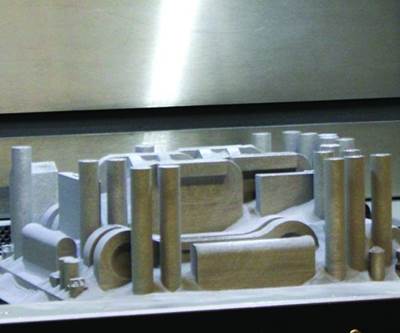

Read MoreFunctional Prototyping

Using AM rather than conventional methods offers companies speed and flexibility.

Read MoreAre AM Parts as Strong?

The technology’s use for replacement of a flight-critical part says they are.

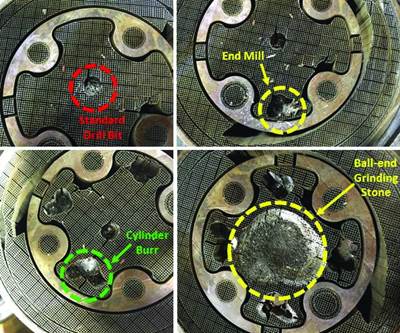

Read MoreRemoving Metal Supports from Additively Manufactured Parts

What is the best way to remove metal support structures from AM parts?

Read MoreWill My AM Part Explode?

Not if you’re careful. Parts built from metallic powder require extra precautions.

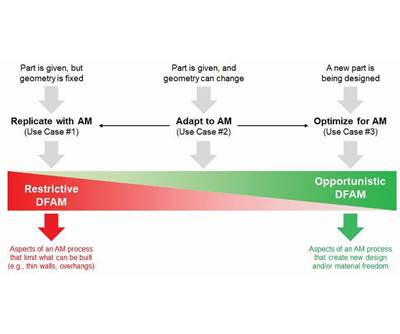

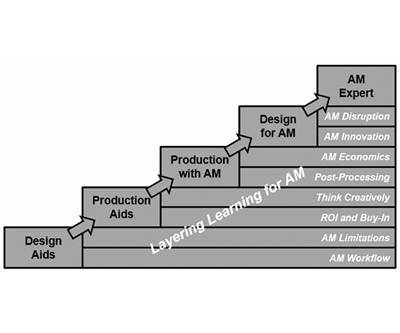

Read MoreEasing into AM

A layered approach to learning the technology will help lessen the headaches.

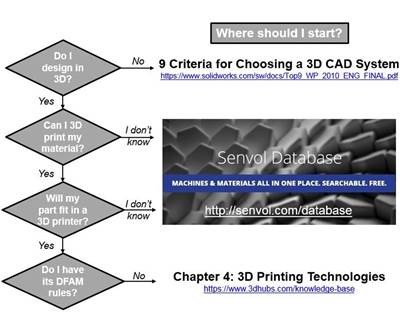

Read MoreWhere Do I Start with AM?

Here are a few more basic questions to ask yourself before diving in.

Read MoreTrade-offs with AM

Current design tools and process workflow are inadequate to meet our needs.

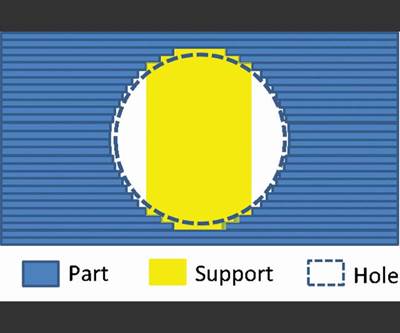

Read MoreWhy Are Holes Circular?

Geometries that are easy to machine may not be easy to fabricate additively.

Read MoreWanted: Flexible Shops and Open-Minded Pros

AM is more complicated than the hype implies. It needs creative people to advance its adoption in this industry.

Read More