-

SPONSORED

-

-

Milling Tools

Tungaloy Launches Small Diameter Indexable Shoulder Milling Cutter

The new size-04 inserts for the TungForce-Rec series enable the cutter body to have a large core diameter and ample insert support, providing high tool rigidity and stability contrary to the small diameter.

Read MoreEmuge-Franken USA Expands End Mills Range

Emuge-Franken USA’s Top-Cut VAR end mills feature flute and profile geometries that are said to be optimized for long tool life and superior performance in both roughing and finishing applications.

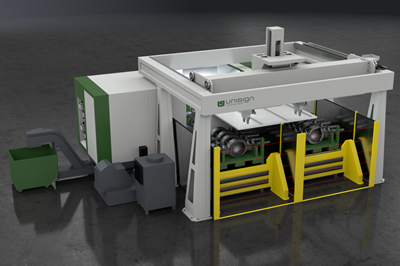

Read MoreUnisign Machine Tools Launches New CNC for Truck Industry

Unisign’s Uniaxle CNC machine enables simultaneous milling and drilling on both axle ends. It provides a dedicated CNC machining center where welded and cast rear axles can be machined in a single setup

Read MoreHigh-Performance Chip Splitter Maximizes Metal Removal Rate

Hanita’s VariMill Chip Splitter is said to deliver higher metal removal rate (MRR) by separating long, undesirable, stringy chips from deep cavities and dynamic milling paths by cutting material into shorter, more manageable sections.

Read MoreWalter Introduces New Milling Grade That Finishes With One Cutting Edge

Walter’s new WHH15X milling grade can reportedly provide extra-long tool life, especially with hardness of 58 HRC or greater. The new grade can be used universally for finishing on ISO materials P, K and H, and is said to be ideal for copy milling in die and mold making.

Read More3D Printing Lightweights Large Cutting Tools

Larger parts require larger, heavier cutting tools. 3D printing enables Star SU Neher to produce lightweight large tool bodies and add features that improve tool life and performance.

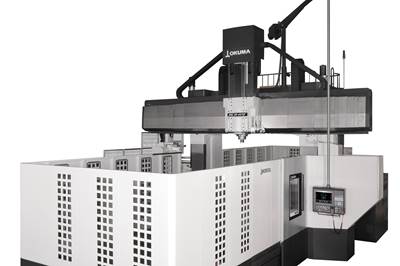

Read MoreOkuma Launches New Double-Column Machining Center

Okuma’s MCR-BV is capable of five-axis contouring and five-sided heavy milling applications. The company says these heavy-duty applications are made possible through the machine’s powerful integral motor and spindle, as well as an expanded work envelope.

Read MoreEnd Mill and Collet Combo Cuts High-Speed Machining Costs 62%

Switching to Emuge-Franken helped precision production machine shop SB Dezigns save 62% in costs on a popular automotive part while lowering cycle times.

Read MoreNew Milling Series From Kyocera Provides Deeper Depth of Cut

The MFH-Max reduces the number of passes needed to machine the workpiece with its ability to take on deeper depths of cut (max. 0.098" / 2.5 mm).

Read MoreA More Efficient Way to Cut Near-Net Parts

Choosing the right milling insert is important: This insert from Iscar is designed for finishing near-net shaped parts quickly, while another makes high-feed machining more accessible with existing machining centers.

Watch