-

SPONSORED

-

-

Milling Tools

Walter Increases Strength and Teeth of Xtra-Tec XT M5130

Walter has revised its Xtra-Tec XT M5130 shoulder milling cutter, increasing its productivity with more teeth, an enhanced clearance angle and a new insert-mounting position.

Read MoreWalter Xtra-tec XT M5012 Comes Fully Ground or Sintered

Walter’s Xtra-tec XT M5012 ships in fully ground and sintered configurations, increasing the cost-effectiveness and precision of this versatile face mill.

Read MoreWhy Binderless CBN Inserts Turn Titanium Faster

A new formulation of cubic boron nitride could provide a more solid alternative to cemented carbide as finish-machining becomes more demanding.

Read MoreCarmex Multi-Function Milling Tool is Versatile, Durable

Carmex’s Multi-Function Milling Tool performs six milling operations on a single tool, while maintaining high performance and durability.

Read More2021 Will Be Dramatic, Too — How Is Your Tooling?

The time is now to take stock of your tools. Recently posted articles explore the potential impact of tooling technology.

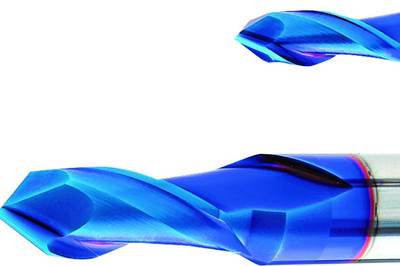

Read MoreKennametal Says Its PCD Tools Outperform Carbide Tools

Kennametal has debuted a line of PCD tools, including drills, reams and end mills, that it says improves upon carbide tooling for aluminum and aluminum-alloy machining.

Read MoreWalter M5137 Xtra-tec XT Cutter Reduces Finishing Operations

Walter’s M5137 Xtra-tec XT shoulder milling cutter features 90-degree approach angles, which it says reduces the need for additional finishing operations.

Read MoreBig Kaiser Introduces LiveChat Services

Big Kaiser has introduced a LiveChat service to its website, providing real-time chat support during normal business hours and an after-hours message service.

Read MoreSandvik CoroMill 390 LW Enhances Aerospace Machining Capacity

Sandvik Coromant’s 3D-printed CoroMill 390 cutter helped Flying S Inc. achieve six-times the productivity on MAX5 cast aluminum alloy than with previous tools.

Read MoreGreenleaf Boosts OCCO's Cutter and Insert Productivity

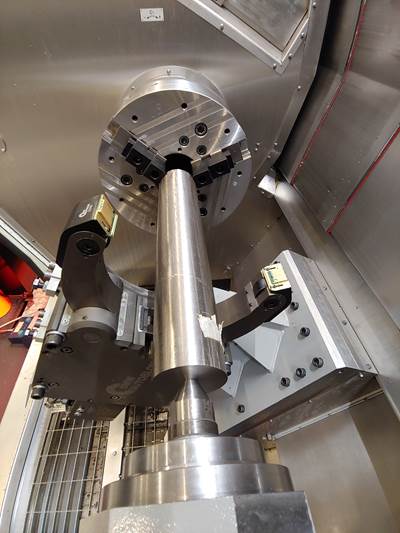

Greenleaf Corp.’s proprietary insert, cutter and machine adjustments helped OCCO reduce crankshaft machining costs to, in some cases, a quarter of the original cost.

Read More