-

SPONSORED

-

SPONSORED

Software

Standard Tool Classification for Better Data Communication

Cutting tool manufacturers have worked together to create a generic tool catalog format that helps link cutting tool information with applications supporting data-driven manufacturing.

Read MoreCAM Software Cuts Production Time, Increases Quality

Performance Motion's business growth necessitated increased efficiency and expanded capabilities. Implementing Vero's WorkNC CAM software reduced cycle times, improved quality and expanded capabilities.

Read MoreRobot Cell Simulation Software Reduces Errors, Promotes Efficiency

Yaskawa Motoman’s MotoSim EG-VRC version 5.2 is a comprehensive software package that provides accurate 3D simulation of robot cells.

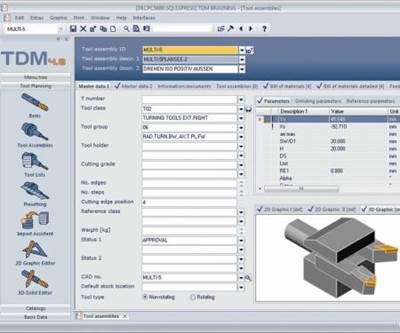

Read MoreTool Lifetime Management Software Supports Multi-Functional Tools

TDM Systems has released version 4.8 of its TDM software designed to optimize tool lifecycle management (TLM) as part of Industry 4.0 and Industrial Internet of Things initiatives.

Read MoreOpen-Protocol Device Enables Connectivity for Legacy Machines

Mazak’s open-protocol, MTConnect-compliant SmartBox is intended to be a platform for secure entrance into the Industrial Internet of Things, designed to facilitate connectivity of machines and devices and enhance monitoring and analytical capabilities.

Read MoreDNC Box Enables CNC File Transfer via USB

Highland DNC’s ShopLink Flash USB-to-RS-232 adapter enables transfers of DNC program files to and from CNCs via flash drives.

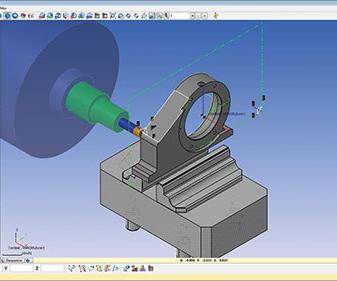

Read MoreSimulation Software Enables Direct Download of OEM Tool Geometries

CGTech and MachiningCloud have jointly introduced a feature that enables users to import an entire tooling package into Vericut 7.4.

Read MoreBusiness Software Reduces Project Time by 75 Percent

When order processing time was on the rise, Southfield Packaging implemented Exact Online for Manufacturing business software to streamline its processes and view real-time business insight anytime, anywhere.

Read MoreReal-Time Tool Monitoring

Machine operators have long dreamt of a process monitoring system that detects tool wear, and potentially catastrophic conditions and automatically compensates for changes in tool geometry after resharpening. Now that dream is a reality.

Read MoreBearing Down on Industry 4.0

A research project in Europe is developing what could conceivably be the prototype for machine tools ideally suited for implementing data-driven manufacturing within the Industry 4.0 framework. One of the most interesting aspects of the project is embedding digital sensors in the bearing components inside the machine tool.

Read More