-

SPONSORED

-

SPONSORED

Tooling

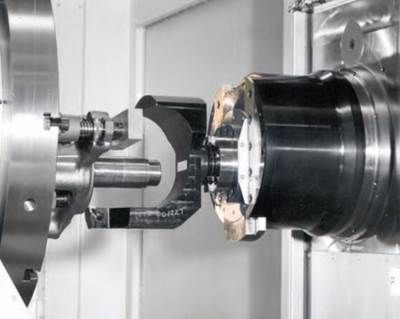

HMC Delivers Turning, Drilling, Milling with Single Clamping

The Heckert DBF 630 HMC, available from Starrag, enables turning, drilling and milling of non-rotational, asymmetrical parts in a single clamping with one toolholder.

Read MoreExtreme Part-Off Demos at IMTS 2014

The strength of part-off tools is shown in demos whereby they part off a railroad rail and sledge hammer head. Talk about significant interrupted cuts…

Read MoreSystem Enables Fast Fixturing

Carr Lane Manufacturing’s latest 768-page catalog features its Carr LockTM products for fast fixturing.

Read MoreIndexable Mini Angle Head Enables Multi-Position Machining

Eltool's indexable mini angle head can mill and drill in bores or cavities as small as 5/8" in diameter.

Read MoreOnline Marketplace for Surplus Tooling

Industrial Surplus Solutions has launched toolingmarketplace.com, an online resource to facilitate the buying and selling of surplus cutting tools.

Read MoreVMC Equipped with FSM for Unattended Operation

Okuma will display its vertical machining center equipped with a Palletace flexible manufacturing system (FMS) for unattended operation.

Read MoreWebinar: Increase Milling Output on Your Existing Machine

It is not always the strength of the tool or the power of the machine that limits your depth of cut. In many cases, the limitation is the tendency to vibrate. Learn how to mill more productively by selecting spindle speeds tailored to your machine’s dynamics.

Read MoreClamping Options for Five-Axis Machining

In five-axis machining, the workholding has to get out of the way. The wrong choice of clamping risks collision and can obscure one of the principal benefits of a five-axis machine.

Read MoreTangential Milling, Slow-Motion Video Address Slotting Bottleneck

By switching to tangential milling from Ingersoll Cutting Tools and using a slow-motion video to identify and overcome a lack of horsepower, Busche Enterprise was able to reduce cycle time and tool cost.

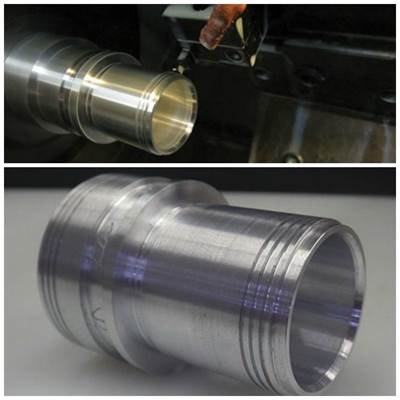

Read MoreThe Right Tools for Micro Grooves

Mack Tool and Engineering used modified inserts to create micro-grooves, but they were prone to breaking. After switching to Thinbit Groove ‘N Turn tools from Kaiser Tool, the company experienced increased tool life.

Read More