-

SPONSORED

-

SPONSORED

Tooling

Dual-Contact Toolholders

The Rego Plus line of toolholders from Rego-Fix is licensed by BIG Dishowa and is designed for high-precision milling with virtually all BIG Plus spindles.

Read MoreCoated Turning Grades for Increased Tool Life

Tungaloy America’s CVD-coated T9100 steel turning series features a “PremiumTec” coating, which is a special surface technology that gives the insert a highly polished cutting surface.

Read MoreCarbide Milling Cutters for High-Productivity Metal Removal

Seco’s Jabro-Solid2 (solid square) carbide milling cutter is available in sizes ranging from 1/8" to 1". The versatile, square-shoulder mill is designed for both wet and dry general-machining applications in a variety of materials, including carbon steels, gray cast iron, stainless and super alloys.

Read MoreMini High Feed Cutter with Four Edges

The Power-Feed+Mini high feed cutter from Ingersoll Cutting Tools features a high speed geometry with a double-sided, four-edged insert.

Read MorePortable Shrink-Fit Machine

Lyndex-Nikken’s shrink-fit machine firmly inserts cutting tools into shrink-fit holders in 2 sec.

Read MoreMills for Higher Removal Rates at Moderate Feeds

Iscar says its new milling cutters increase productivity in heavy roughing applications on limited-feed machines.

Read MoreHorizontal Boring and Milling Machine

Mighty Viper offers the PBM-135 precision CNC horizontal boring and milling machine with a rotary table.

Read MoreIndexable Mills Speed Cavity Cutting

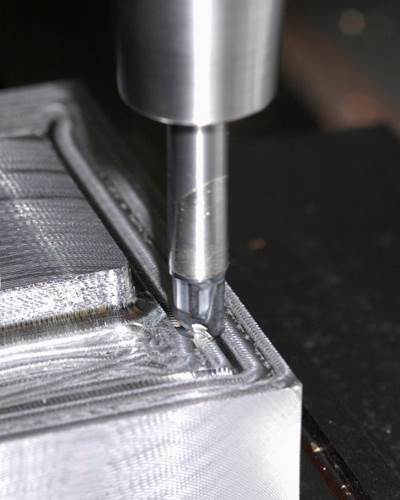

Ballnose mills are a common choice for hogging out cavities on molds and form dies. However, these three shops have realized significantly faster cavity milling by switching to Ingersoll’s Chip Surfer modular tooling system, which features a cylindrical shape that keeps more of the tool engaged in the cut.

Read MoreRotary Tables Save Time, Expand Capabilities

This shop refused to accept the notion that large, complex parts necessarily require multiple, time-consuming setups. Rotary tables from Lyndex-Nikken have saved time and expanded capabilities to the point where the shop can take on new work and bring previously outsourced jobs back in-house.

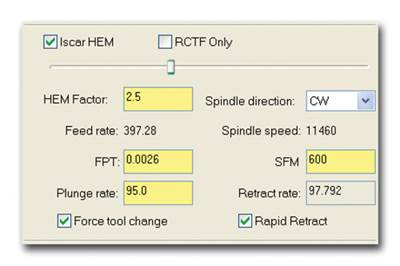

Read MoreSoftware/Tooling Partnership Promises Easier HSM

High-efficiency parameters are calculated automatically—partly using a slider that lets the programmer set the level of aggressiveness.

Read More