-

SPONSORED

-

SPONSORED

Tooling

Insert Grade for Milling Tool Steels

Dapra’s DMK25 insert substrate features a micro-grain structure with medium cobalt content, providing very good edge strength and wear resistance while maintaining outstanding toughness, the company says.

Read MoreHigh-Performance Taps for Demanding Applications

Widia’s high-performance WIDIA-GTD HSS-E taps are designed for increased precision and productivity in thread-making applications.

Read MoreToolholder Extension Increases Tool Life

Schunk says its hydraulic expansion extension Tendo-SVL transforms virtually every precision toolholder into a highly versatile specialist for narrow spaces independent from the spindle interface.

Read MoreSolid Carbide Thread Mills

An expanded line of solid carbide thread mills has been added to the company’s Threads-All program.

Read MoreCarbide End Mills Feature Four-Flute Design

Superior Tool Service offers a four-flute rougher/finisher carbide end mill for cutting hard steel.

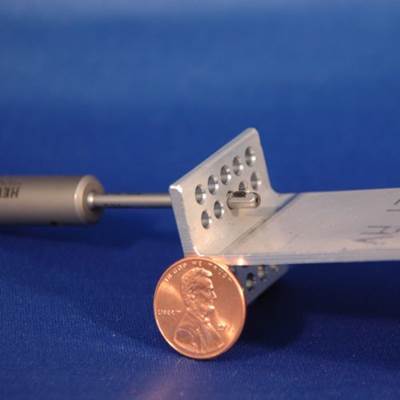

Read MoreFront and Back Chamfering Tool for Small Holes

The Micro Snap series of carbide deburring tools is suited for all-purpose, single-pass, front and back deburring and chamfering of through holes measuring between 0.079" and 0.197" (2 and 5 mm).

Read MoreComposites Machining for the F-35

Lockheed Martin’s precision machining of composite skin sections for the F-35 provides part of the reason why this plane saves money for U.S. taxpayers. That machining makes the plane compelling in ways that have led other countries to take up some of the cost. Here is a look at a high-value, highly engineered machining process for the Joint Strike Fighter aircraft.

Read MoreFind Your Speed Outside of Machining

This short-lead-time mold shop achieves its most significant time savings by looking outside the machining cycle. However, one of those elements outside the cycle—palletized setup—ultimately led to cycle time savings via five-axis machining.

Read MoreWhat Don’t you Like About that Canned Cycle?

Almost all CNC users take advantage of control-based canned cycles. Even CAM systems commonly output G-code programs that contain canned cycle commands. This includes hole machining canned cycles, such as drilling, tapping, boring and more, and whatever milling cycles the machine may have. For turning centers, it includes roughing and finishing multiple repetitive cycles.

Read MoreBenchmark Your Machining Knowledge

Ryan Pohl, president of Expert Technical Training, says his company gives a 20-question, multiple-choice test to shops to evaluate their need for his firm’s “Advanced CNC Milling and Drilling” course. The questions cover important points—though not necessarily basic points—related to tools, toolholders, machine design and cutting parameters. Here is a link to the questions.

Read More