Articles

For Laser Shops: Oxidation Retaliation

In an effort to prevent field paint failures, OEMs can no longer accept parts with the oxide buildup. A mechanical means of removal such as hand buffing or grit blasting is commonly practiced. However, these time-consuming and often labor-intensive processes can represent a substantial expense, and they can also introduce inconsistencies.

Read MoreWireless Collection Of Measurement Data

In manufacturing, reacting to measurement data in a timely fashion is critical. A fast response to undesirable trends can prevent scrap or rework. The problem is, it can be slow and cumbersome to collect, deliver and analyze measurement data. Recent efforts to expedite this process have included shop-wide cable networks with bar code readers and other automated devices. The latest development along these lines is wireless data handling.

Read MoreMove The Program Instead Of The Part

A complex five-axis part with hard-to-reach datums is machined in two setups instead of eight, thanks to a process that rewrites the tool paths to match the part's position.

Read MoreMaking Strides To Maximize Worker Efficiency

This 40-year-old shop combines original best practices with new technologies and manufacturing approaches to make the most of its home-grown skilled labor.

Read MoreFinishing Process Extends Life Of Cutting Tools And Components

By applying compressive forces and abrasive media to cutting tools or workpieces, this surface finishing process improves component wear resistance and lubricity.

Read MoreToward More Seamless MQL

One of the small perils of a new technology is that it often involves new steps or new considerations that present special opportunities for error. Minimum quantity lubrication (MQL) is a technology that exemplifies this point.

Read MoreThe Value Of Daily CMM Capability Checks

Coordinate measuring machines are not infallible. A variety of factors can adversely affect their measuring accuracy, including a crash, large temperature fluctuations, a malfunctioning probe head, use of an uncalibrated probe - even a person leaning on the machine gantry might be enough to take it out of square. If the CMM's true capability is verified only once a year via laser or another calibration method, then it's possible that the CMM might be inaccurately measuring parts for an extended period of time, unbeknownst to the operator. The question remains - did a workpiece fail inspection because of an imprecise manufacturing process or an inaccurate CMM?

Read MoreA Study Of The Steady Rest

When the length and stiffness of a workpiece make it difficult to machine, many turn to the steady rest.

Read MoreThe Time Is Right For IMTS

Investing in the latest manufacturing technologies is one of the keys to succeeding in a global manufacturing marketplace. The time to do this is now.

Read MoreThe Power Of The Continuous Improvement Event

The continuous improvement event (CIE), called the Kaizen event by some, has proven to be a valuable tool for introducing positive change in an organization. Such an event targets a specific area in the organization where employees can work together to implement improvements quickly.

Read MoreAerospace Hole Making Takes Shape

The demand for fast hole making will intensify as more fuel-efficient jet engines are introduced. Electrical discharge machining is emerging as the answer.

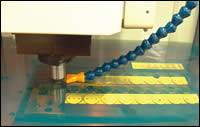

Read MoreMainstream Technology Keeps Shop On Track

In its toolroom, Branchline Trains takes a practical approach to machining with end mills as small as 0.005 inch in diameter.

Read More