Articles

Practical Tips For High Speed Machining Of Dies And Molds

In die/mold work, the programmer can make the HSM process dramatically more effective. Here are some tips.

Read MorePart Finishing And The New RoHS And ELV Directives

New environmental directives that have come out of Europe and Asia limit the toxic chemical content in manufactured products in order to protect users and to facilitate the recycling of these components. Restriction of Hazardous Substances legislation limits hazardous metals contained in electrical and electronic components. The ELV (End-of-Life Vehicle) Directive limits polluting metals that can be contained in vehicles in order to minimize hazards caused by recycling their components. In order to comply, manufacturers will have to consider finishing processes such as a low-temperature black-oxiding process that does not use banned substances or leave them in the finished product.

Read MoreMaking Programming Hands-Free (Almost)

Feature-recognition CAM software helps this technology company's internal mold shop deliver critical molds more quickly. A programmer is still needed, but the software automation saves considerable time.

Read MoreMeasuring Tool Length For Micron Accuracy

Measuring the length of the cutting tool in the spindle is critical.

Read MoreIs It A Mill, A Waterjet Cutter Or Both?

An enclosed waterjet module that installs on a shop's existing knee mill or VMC temporarily transforms that equipment into a waterjet cutter.

Read MoreAn Affordable, Secure Way To Exchange 3D CAD Models

Shops no longer need 3D CAD software to view 3D CAD models.

Read MoreTeaching With Technology

A North Carolina machining instructor says the industry should give community colleges a second look.

Read MorePhotogrammetry Collects Precision 3D Data In Unlikely Places

Remember when computing technology was changing so fast that your new computer was almost antiquated in just a few months? Digital photography and imaging technology is following a similar pace, with cutting-edge developments rolling off the assembly line in record time. What does this have to do with industrial measurement, you ask? Plenty.

Read MoreAerospace OEMs Back A Lean Sea Change

A lean enterprise initiative comprised of aerospace primes and their suppliers, attempts to bring commonality to the supply chain. Its strategy is to provide a gage to measure lean progress and a roadmap to the higher levels of process maturity.

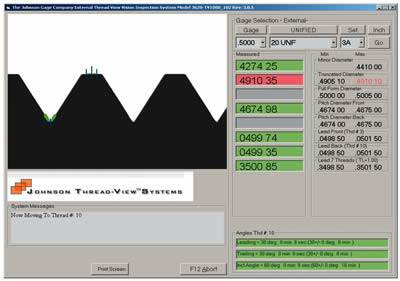

Read MoreAutomating Thread Measurement

This automated, non-contact measurement system can eliminate operator errors when measuring UN series threads on thread gages and workpieces.

Read MoreSizing Up The Management Challenge

The demand for extremely small precision components is growing. A look at one company's thrust to meet this demand reveals what it takes to run a micro machining business.

Read MoreInspection For Free

Gaging integrated with a robot delivers inspection without any cost in floorspace or cycle time.

Read More