Articles

Chip-Free Drilling Process Creates Holes And Bushings

This chip-free drilling technique can create both a hole and support bushing in thin-walled parts in one machining operation.

Read MoreThe Real Cost Of Runout

A seemingly small amount of runout can still be too large for the tool. Reduce this runout, and tool life or productivity may dramatically increase.

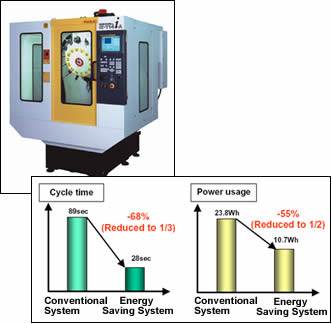

Read MoreCut Faster To Save Energy Cost

High speed machining and other control-related technologies offer real potential for reduced energy costs.

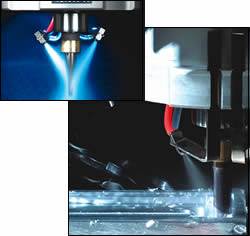

Read MoreAlcohol-Based Coolant Offers Environmentally Friendly Machining

This micro-volume coolant delivery system uses ethanol as the cooling medium for non-ferrous workpieces. The ethanol evaporates after it cools the cutting tool, so no residue is left behind on machined workpieces.

Read MoreSucceeding Beyond A Specialty

This shop watched its chosen niche become less profitable. Its response was a dramatic investment in new equipment, along with an information-related change that has made all of the shop’s equipment more cost-effective.

Read MoreSpain Continues To Focus Abroad

This year’s BIEMH show proved that Spain’s machine tool builders, as well as its tooling and accessory manufacturers, are looking outward to a growing global market.

Read MoreSwitzerland Is Learning To Be Lean

Earlier this year, visited a cross section of metalworking manufacturing companies in Switzerland to find out how they are meeting the challenge of globally competitive manufacturing.

Read MoreMachining’s Role In Making Cancer "History"

A machine shop in a new cancer treatment center produces components to precisely guide proton radiation to eliminate its target—cancerous tumors.

Read MoreDirect-From-CAM Machining Streamlines Robotic Milling

The controller on this robotic milling system drives robot movement directly from a CAM model without requiring a postprocessor to generate machining code.

Read MoreA Two-Speed Approach To Plunge Roughing

In plunge roughing, the strategy is in the stepover. Here is a plunge roughing strategy that has worked well for Boeing researchers.

Read MoreThinking Big

This shop specifies large machine tools for the machining possibilities of the future. To prepare for the feed rates the shop expects to use one day, the latest large gantry mills apply linear motors on all three linear axes.

Read More