-

SPONSORED

-

SPONSORED

-

Tooling

Job Shop Finds Its Niche With The Help Of Tapping Machines

The metalworking job shop market can be illustrated as a pyramid. At the base of the pyramid is the largest segment of the discrete parts manufacturing business.

Read MoreHeavy-Duty Hole Making

A modular drilling and boring system has changed this oilfield product manufacturer's holemaking operations.

Read MoreDeep Thinking

A job shop that specializes in gundrilling points out the special requirements of machining deep holes.

Read MoreSecuring A New Process

A Minnesota manufacturer of precision parts boosts productivity by expanding its workholding capacity.

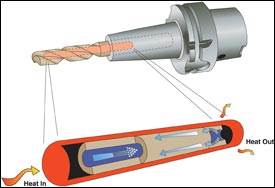

Read MoreDrilling Dry With A Heat Pipe

It's widely known that hole making is, by a significant margin, the most frequently performed process among metalworking operations. It's also among the most difficult operations to control from a thermal perspective.

Read MoreAnother Way To Square—Or Is It Perpendicular?—It Up

There are a number of tools available for shop personnel to evaluate the right angle relationship between two surfaces. The basic machinist square has a number of variations, the most common being the hardened steel square used to check right angles and set up milling and drilling machines.

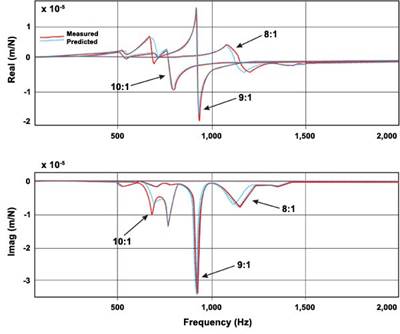

Read MoreThe Overhang Effect

The length by which the tool extends from the toolholder is a variable that can be used to 'tune' the machining process. Contrary to what you may expect, increasing the tool's L:D ratio may reduce chatter and result in more productive milling.

Read More