-

SPONSORED

-

SPONSORED

-

Tooling

Small-Diameter Drilling Under Scrutiny

Today's smooth-running high rpm spindles not only allow shops to cut faster with standard tool designs, they also unlock the potential of tiny tools.

Read MoreFaster Off-Line Setup Helps Reduce Turret Tool Costs

At this company, a contract manufacturer specializing in sheet metal fabrication, finding ways to get more out of its turret punching operations has become a passion.

Read MoreA Better Process For Hole Making

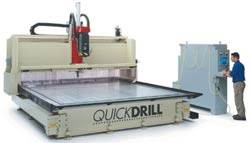

This company is in the business of drilling millions of holes in very large parts. As an established manufacturer of heat exchangers and components, the Calgary, Alberta-based company drills an estimated 1.5 million holes per year in metal plates.

Read MoreOn The Path To Automation

Implementing an integrated tooling system proved to be this mold shop's first step toward automated operation of its electrical discharge machines and graphite mills. Today, the shop's robotic cells can run around the clock in an unattended mode.

Read MoreWhy Use Hydraulic Toolholders

The book on hydraulic toolholders is that they are fussy to set, fragile to operate and expensive to buy. So why do many shops choose them over other holders that seem less demanding? This Chicago mold builder has good reasons for its choice.

Read MoreInserts For Difficult Materials

Economic efficiency is an important consideration when choosing tools for challenging metals.

Read MoreManufacturer Halves Cycle Times With Machining Center

The complex shapes of the iron castings that make up the housings for this company's flow meters require machining on multiple faces. The castings undergo various types of machining operations, from drilling to helical thread milling.

Read MoreAutomatic Pallet Systems Increase Production And Quality

These pallet changer systems not only improved this tooling manufacturer's labor situation, but they managed to increase their production as much as 600 percent on some of its indexable cutting tool products.

Read MoreOne Stop Milling, Drilling, Turning And Grinding

Many shops, in an effort to reduce the handling of workpieces and get takt times (time spent in the cut) as low as possible, are looking to streamline this traditional hurry-up-and-wait process scheme.

Read MoreMills Hard Powder Metal With CBN Inserts

This shop machines hard, abrasive metal components for plastics-compounding and extrusion machinery. The components are barrels and screws used in machines for mixing and compounding plastic, food and industrial products.

Read More